| Mounting | Base Mounted |

| Release | Screw Release |

| Volume Per Stoke Large | 2.65 |

| Oil Reservoir | false |

| Body Material | Steel |

| Piston | Low Pressure, Hard Chrome Plated Steel - High Pressure, Brass |

| Maximum Pressure Rating | 20,000 PSI |

| Piston Diameter | 1 1/2-5/16 in |

| Volume Per Stroke Small | 0.11 |

| Lever Load per 1000 PSI | 3/8 |

| Outlet Port Size (NPTF) | 9/16-18 Straight Thread (see drawing) in |

| Net Weight | 23 lb |

| Operating Lever Size | 24 in3 |

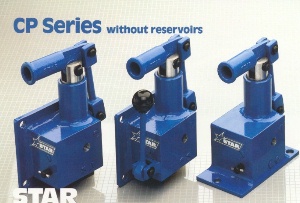

CPS04-LR

With Adjustable Overload Relief Valve

With Manual Pressure Release Valve

Without Reservoir

These pumps, either base or flange mounted style without oil reservoirs, are used on equipment that has its own built-in reservoir. These 2-speed pumps provide rapid movement at low pressure for the part of a cylinder’s stroke where no work is encountered. The pump automatically switches to high pressure when the cylinder must deliver maximum push or pull force. Changeover from high volume-low pressure to low volume-high pressure occurs at approximately 300 PSI and is automatic-no need to shift lever or interrupt pumping. Hand operated models have a choice of screw or cam release. The adjustable overload valve will be set at the maximum pressure at the factory unless a lower pressure is specified by the customer. The overload can be adjusted by the customer in the field, if required.

Features:

- 2 speed pumps that provide pressure up to 20,000 PSI

- Rapid movement at low pressure when minimal work is needed

- Switches to high pressure to deliver maximum force

- Automatic changeover occurs at approximately 300 PSI

- Base and Flange mounting options are available

- Foot operated versions are available

- Includes Manual Pressure release valve with screw or cam release

- Customer specified overload relief valve setting

- Does not include a reservoir

- Supplied with a 24″ operating lever

- Available in Stainless Steel

Design Details:

- Steel pump bodies

- Piston ground and hard chrome plated

Design Notes:

- Factory overload will be set at maximum unless a lower pressure is specified by the customer. To specify a pressure, add to end of the part number (ex: CPS13-LR-8000)

- PL pumps do not have threaded inlet ports. They must be gasket mounted to a reservoir

- All CP04 style pumps have a unique port to handle the high pressure requirements. See the CP04 port drawing for detailed information on this port configuration.

Downloads

- Limited Warranty

All Star pumps are covered by a limited warranty on materials and workmanship for one year from the date of manufacture. Star will repair or replace at its option any pump in which Star finds manufacturing defects. In order to get warranty service a pump must be returned to the Star plant freight prepaid with a written explanation of the problem.

Technical Data

Light hydraulic oil is recommended for use with Star pumps. Oils with SUS viscosity of 75 to 150 at 100 degrees Fahrenheit will give satisfactory performance (ISO grade 15, 22, or 32). In an emergency situation when the above oils are not available, use 5 W or 10 W motor oil or automatic transmission fluid.

All exposed surfaces of standard Star pumps are painted with one coat of industrial quality paint. Pumps painted with special colors with two coat finishes, or with prime coat only, and pumps with special plated or polished parts, are also available.